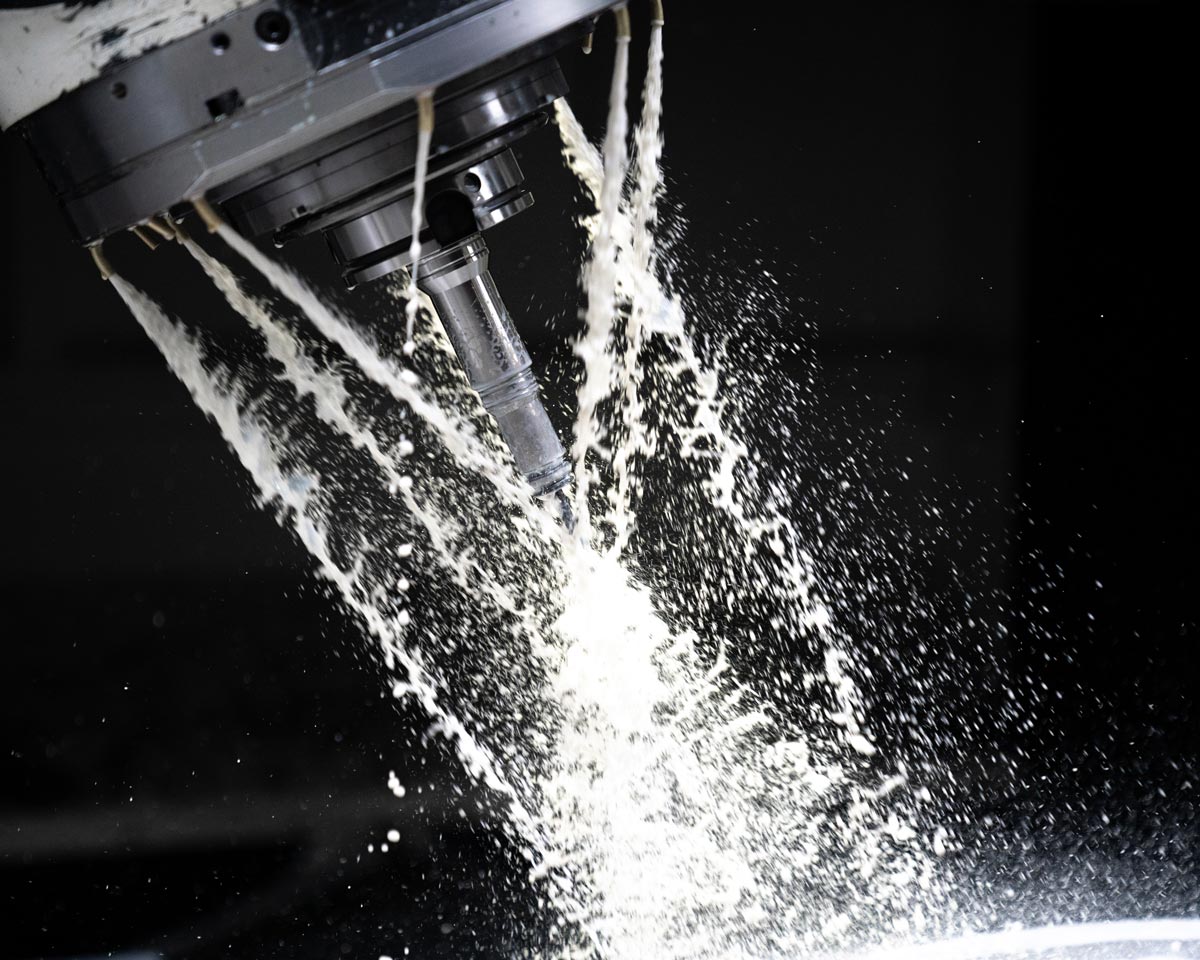

Premium Series: Water Dilutable Cutting Fluid

Premium Heavy Duty Metalworking Fluid

XTREME CUT 250C is a premium quality, heavy duty metalworking coolant. It is designed to provide optimum tool life and surface finishes on a wide variety of materials including aluminum, titanium, nickel alloys, and most other ferrous and non-ferrous materials.

XTREME CUT 250C is well-suited in aerospace, motor-sports, electronics, and other shops that prefer one coolant to cover both high speed machining of aluminum and precision machining of hard metals. XTREME CUT 250C uses a unique surfactant package that delivers low usage rates compared to most high lube products, thus reducing the cost of use. It is also designed to reduce maintenance costs through its low foam properties, low drag-out rate, low residue, and very long service life.

XTREME CUT 250C does not contain animal fats or derivatives, heavy metals, chlorinated or sulfurized EP additives, zinc, calcium, free boric acid, nitrites, diethanolamine, silicone, formaldehyde, MBM, phenols, PCBs, phthalates, dioxins, or PIP (3:1).

XTREME CUT 250C is packaged in totes and drums. Buckets and pails are also available. Consult with your local QualiChem Distributor or QualiChem Sales Engineer to discuss available water quality, application conditions, performance criteria, recommended dilutions, and machine cleaning procedures (if applicable). Refer to the Safety Data Sheet (SDS) for additional physical and chemical properties, associated hazards (if applicable), and procedures for safe handling and proper storage.

Refractive Index: 1.0

Concentration % = 1.0 x Brix Reading

QualiChem suggests refractometers that have a Brix scale of 0-10 or 0-20, or digital, and that can be calibrated. We use Atago Master 20T refractometers for most applications. Many brands and styles will work, including digital, if used properly and calibration is maintained.

XTREME CUT 250C is a concentrate. When properly mixed with water, it forms a metalworking coolant. Always add concentrate to water if mixing by hand. For best results, use a proportioning device suited to volumes needed and available water pressure. Avoid using cold or hot water. Know your water quality, and treat as recommended.

Want to try XTREME CUT 250C? Contact us today to speak to a distributor or request a sample.