Premium Series: Water Dilutable Cutting Fluid

Premium Semi-Synthetic Machining Fluid

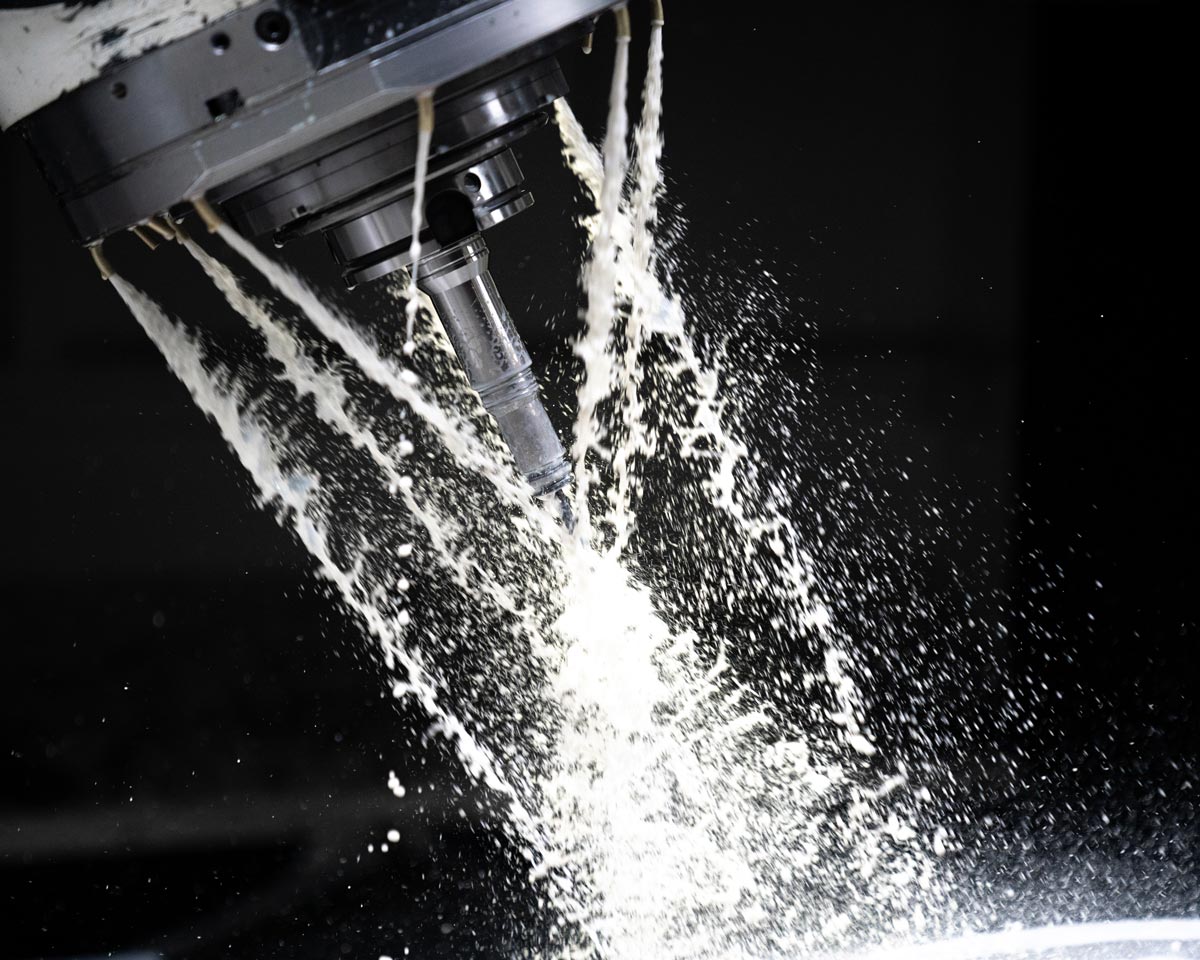

XTREME CUT 230 is a premium semi-synthetic fluid for machining and grinding ferrous and nonferrous alloys. This universal fluid delivers the lubricity and versatility of a premium soluble oil, yet has the cleanliness and heat control of a synthetic. XTREME CUT 230 is designed for use on a wide range of metals, making it well suited for job shop operations. The product's new generation of additive technology improves tool life and part quality without the problems associated with extreme pressure additives such as chlorine, sulfur, and phosphorous.

XTREME CUT 230 also has excellent corrosion control for ferrous metals, a tight emulsion to promote tramp oil rejection, and exhibits excellent hard water stability up to 35 gpg (600 ppm) of hardness. XTREME CUT 230 utilizes state-of-the-art raw materials to prevent the rotten egg odors associated with most soluble oils and semi-synthetic fluids. The fluid runs clean, has excellent bioresistance, and is low foaming. XTREME CUT 230 does not contain chlorine, diethanolamine, formaldehyde release biocides, mercury, nitrites, phenols, silicones, or sulfur.

XTREME CUT 230 is available in pails, drums, totes, and bulk. Consult with your local QualiChem Distributor or QualiChem Sales Engineer to discuss available water quality, application conditions, performance criteria, recommended dilutions, and machine cleaning procedures (if applicable).

QualiChem suggests refractometers with a Brix scale of 0-10 or 0-20, or digital, and that can be calibrated. We use Atago Master 20T refractometers for most applications. Many brands and styles will work if used properly and calibration is maintained.

XTREME CUT 230 is a concentrate. When properly mixed with water, it forms a metalworking coolant. Always add concentrate to water if mixing by hand. For best results, use a proportioning device suited to volumes needed and available water pressure. Avoid using cold or hot water. Know your water quality, and treat as recommended.

Want to try XTREME CUT 230? Contact us today to speak to a distributor or request a sample.