Advanced Series: Water Dilutable Cutting Fluid

GTL-Based Multi-Metal Semi-Synthetic

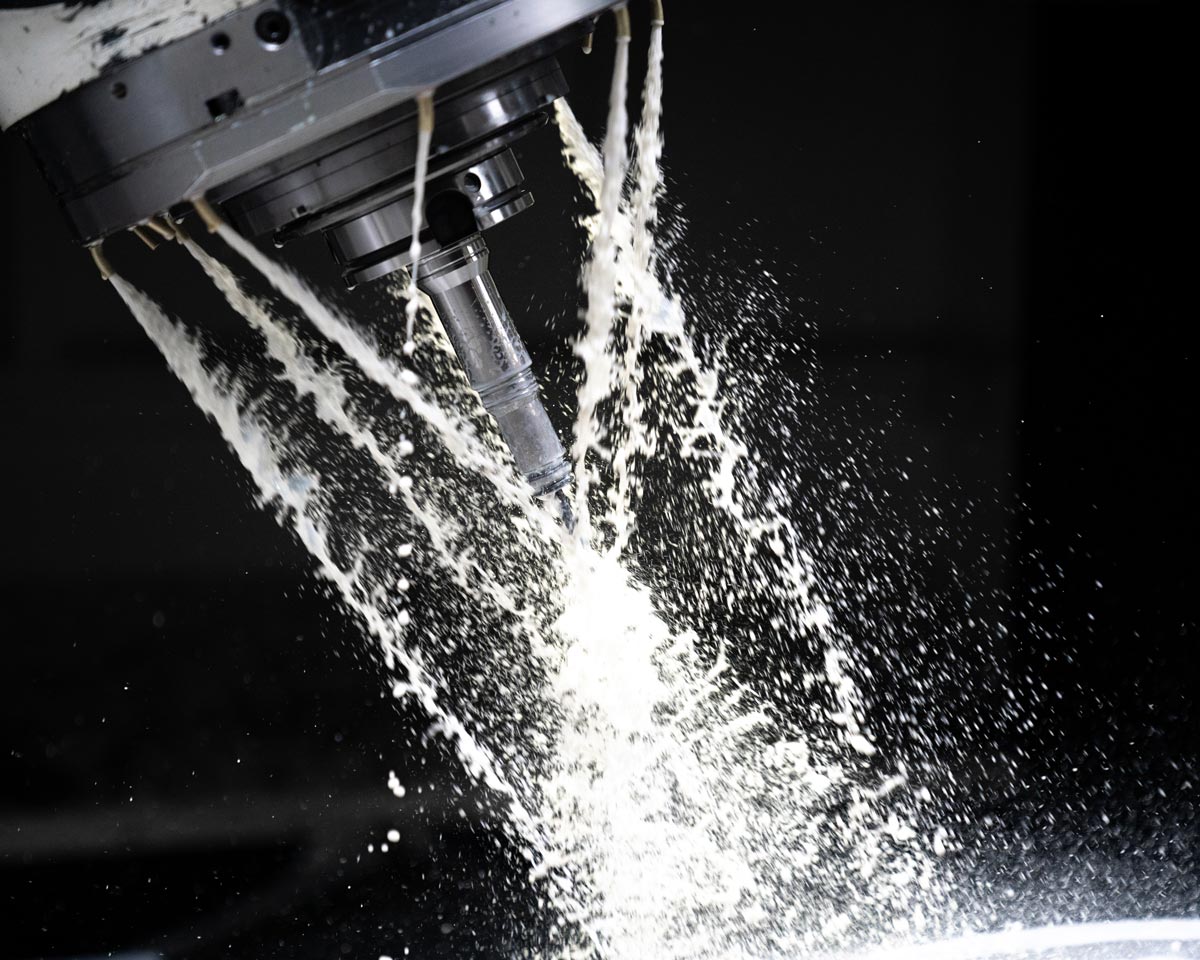

GEOCOOL 890 is a premium Gas-to-Liquid (GTL) based semi-synthetic coolant, designed to excel in difficult applications. This REACH compliant formula does not contain boron, boric acid, chlorine, sulfur, or formaldehyde releasing biocides, making it suitable across all marketplaces. GEOCOOL 890 is safe to use on nearly all materials, including yellow metals, aluminum alloys, cast irons, carbon steels, stainless steels, heat resistant alloys, titanium alloys, and most plastics. It is specifically formulated for materials that are more difficult to machine, such as Ti 6AI 4V and Inconel 718, among others.

GEOCOOL 890 is operator and machine friendly and runs exceptionally clean. It exhibits good foam control in hard, soft, and treated waters. It displays a strong resistance to microbial attack, and its anti-corrosion properties are superior to standard synthetic coolants. GEOCOOL 890 is designed to meet the health, environmental, and safety needs of the global marketplace.

GEOCOOL 890 is available in pails, drums, totes, and bulk. Consult with your local QualiChem Distributor or QualiChem Sales Engineer to discuss available water quality, application conditions, performance criteria, recommended dilutions, and machine cleaning procedures (if applicable). Refer to the Safety Data Sheet (SDS) for additional physical and chemical properties, associated hazards (if applicable), and procedures for safe handling and proper storage.

GEOCOOL 890 is designed for use in metal removing operations involving machining, milling, turning, drilling, boring, threading, and tapping. Also suitable for a variety of grinding applications and light-to-medium duty broaching, forming, and stamping.

QualiChem suggests the use of refractometers that can be calibrated and are either digital or analog. Analog units should have a Brix scale of 0-10 or 0-20. We use Atago Master 20T (analog) or MISCO PA202 (digital) refractometers for most applications. Many brands and styles will work if used properly and calibration is maintained.

GEOCOOL 890 is a concentrate. When properly mixed with water, it forms a metalworking coolant. Always add the concentrate to water if mixing by hand, never add water to the concentrate. For best results, use a proportioning device that is sized for the shop’s needs and available water pressure. Avoid using cold or hot water. Know your water quality and treat as recommended.

Want to try GEOCOOL 890? Contact us today to speak to a distributor or request a sample.